How Are Chemical Vapor Deposition (CVD) Diamonds Created?

Diamonds have long been treasured for their brilliance, rarity, and strength. Traditionally, they were only formed deep within the Earth over billions of years. However, with advances in science and technology, lab-grown diamonds have become a sustainable and ethical alternative to natural diamonds. One of the most popular methods for growing diamonds in a controlled laboratory setting is Chemical Vapor Deposition (CVD). But how exactly are CVD diamonds created? Let's dive deep into the fascinating process.

What is Chemical Vapor Deposition (CVD)?

CVD is a high-tech process used to create high-quality synthetic diamonds in a controlled environment. Unlike High-Pressure High-Temperature (HPHT) diamonds, which mimic the intense heat and pressure conditions of natural diamond formation, CVD diamonds are grown using carbon-rich gases at low pressure. This method allows scientists to precisely control the diamond's growth, resulting in stunning gemstones that are chemically, physically, and optically identical to natural diamonds.

The Step-by-Step Process of Creating CVD Diamonds

- Preparation of the Diamond Seed

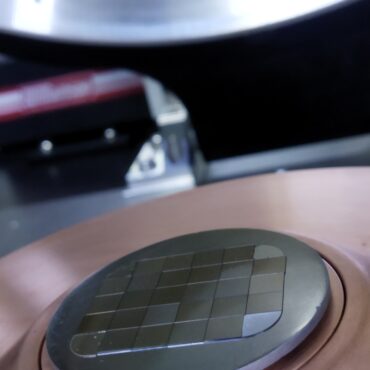

The process begins with a diamond seed, a thin slice of an existing diamond. This seed is usually a high-quality single-crystal diamond, either natural or synthetic, which serves as the foundation for the new diamond to grow.

The seed is thoroughly cleaned using acids and other chemical solutions to remove any surface contaminants, ensuring a smooth and flawless diamond growth.

- Placing the Seed in the CVD Chamber

Once cleaned, the diamond seed is placed inside a CVD reactor chamber, a high-tech vacuum chamber designed to support diamond growth under precise conditions.

- Introducing Carbon-Rich Gases

A mixture of hydrocarbon gases, primarily methane (CH₄) and hydrogen (H₂), is introduced into the chamber. The chamber is maintained at a low-pressure environment to prevent unwanted reactions that could interfere with diamond growth.

- Activation of the Gases with Plasma

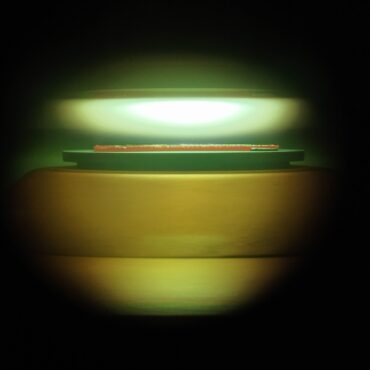

The gases inside the chamber are energized using microwave plasma, hot filament, or other energy sources, creating a high-energy environment that breaks down the molecular bonds of the gases.

This process releases carbon atoms, which are the essential building blocks of diamonds. These free carbon atoms settle onto the diamond seed and start forming layers of crystalline diamond.

- Layer-by-Layer Diamond Growth

The deposition of carbon atoms occurs atom by atom, leading to the gradual growth of the diamond. This step can take several weeks, depending on the desired size and quality of the diamond.

During this period, scientists carefully monitor factors such as temperature (around 800-1000°C), gas composition, and pressure to ensure the best quality growth.

- Cooling and Extraction

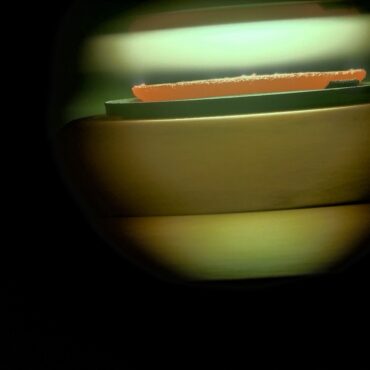

Once the diamond has reached the desired size, the chamber is cooled down, and the diamond is removed. At this stage, the diamond may have a rough surface and require additional processing to achieve a polished and market-ready appearance.

- Post-Growth Treatments

After the diamond is extracted, it undergoes treatments to enhance its clarity and color. These may include:

- Annealing (heat treatment): To improve color by modifying internal atomic structures.

- Irradiation: To enhance or change color.

- Polishing and Cutting: To give the diamond its final shape and brilliance.

Advantages of CVD Diamonds

CVD diamonds have gained immense popularity due to their numerous advantages over natural diamonds and other lab-grown alternatives. Here are some of their key benefits:

- Ethically Sourced & Conflict-Free

Unlike mined diamonds, CVD diamonds are created in a lab, ensuring they are 100% conflict-free and do not contribute to unethical mining practices.

- Sustainable & Environmentally Friendly

Mining natural diamonds requires significant land disruption and energy use, whereas CVD diamonds are produced in controlled environments with a lower carbon footprint.

- Superior Purity & Quality

CVD diamonds often have fewer inclusions and impurities compared to natural diamonds, making them Type IIa diamonds, the purest form of diamond known to exist.

- Customizable Growth

With precise control over the growth process, scientists can produce diamonds of specific qualities, colors, and sizes, catering to various consumer preferences.

Are CVD Diamonds Real Diamonds?

Yes! CVD diamonds are 100% real diamonds, sharing the same chemical composition, physical properties, and optical characteristics as natural diamonds. They are certified by leading gemological institutes like the Gemological Institute of America (GIA) and International Gemological Institute (IGI).

Conclusion

The Chemical Vapor Deposition (CVD) process has revolutionized the diamond industry by offering a sustainable, ethical, and high-quality alternative to mined diamonds. By replicating nature’s diamond-growing conditions in a controlled environment, scientists can produce diamonds that are indistinguishable from their natural counterparts.

Whether you’re looking for an engagement ring, fine jewelry, or an investment piece, CVD diamonds provide an affordable, ethical, and stunning choice without compromising on quality or brilliance.

Would you consider a CVD diamond for your next jewelry purchase?